- Product

-

Solution

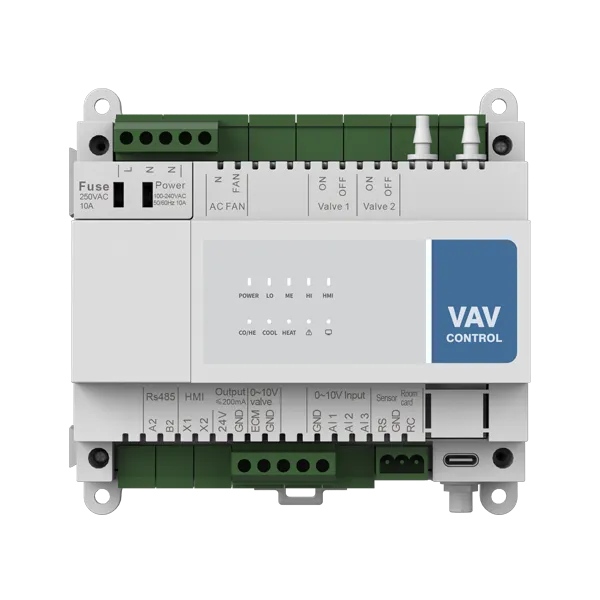

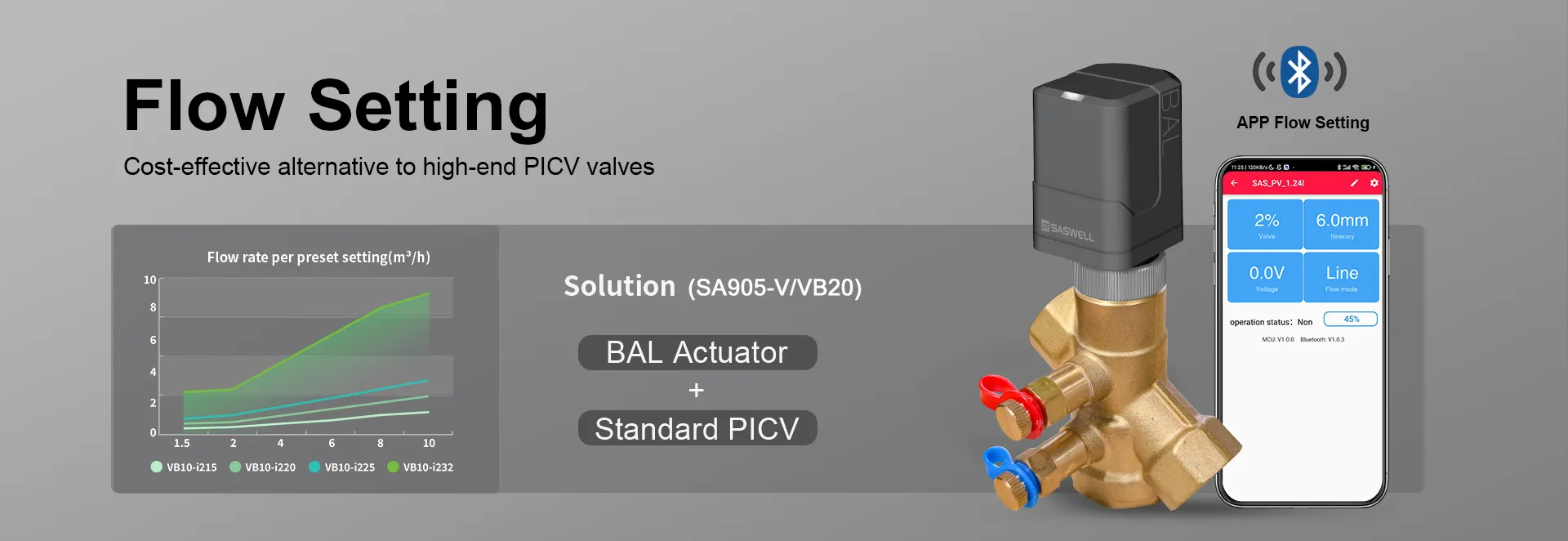

Smart Home HVAC (AC / Floor Heating / Fresh Air) Integration Solution Smart Heat Pump Control Solution Smart Radiator Control Solution Standard Solutions for FCU Terminal Control Universal VAV Control Solution: Empowering Supply Chain Freedom AHU Sensor Solutions Central Air Conditioning Time-Based User Billing System Dew Point Control & Sensing Solutions for Smart Constant-Environment Buildings Digital Energy-Saving Retrofit Solutions

-

capability

capabilityProven by Global Leaders

Our industry capability is built on deep expertise in complex application scenarios and commercial transaction models, proven through long-term collaboration with leading global organizations:

-3 Fortune Global 500 companies in joint development programs

-10 industry-leading customers in deep vertical application partnerships

-5 major world famous Large-Scale DIY retailer as long-term collaborators

-10 global real estate groups across project-based deployments

These partnerships validate our ability to operate effectively across cultures, languages, industries, and diverse go-to-market channels, delivering reliable solutions in complex global environments.

-

Market

Creating Value for Our CustomersEmpowering Clients to Succeed in a Global MarketWe are deeply rooted in diverse markets such as commercial buildings, real estate, home living, energy efficiency, and residential renovation. We offer one-stop solutions—from terminal control products to system integration—with rapid customization as our core strength. By leveraging intelligent connectivity and digital energy-saving technologies, we ensure our clients can stay focused on market development while relying on a partner equally committed to their success. We don’t just make products — we help our customers become industry leaders.

BA Commercial Project SegmentWe provide a one-stop terminal control product package, including thermostats, motorized valves and actuators, and environmental sensors, meeting the multiple requirements for precise control, stable operation, and integration with mainstream BMS systems in building scenarios.

BA Commercial Project SegmentWe provide a one-stop terminal control product package, including thermostats, motorized valves and actuators, and environmental sensors, meeting the multiple requirements for precise control, stable operation, and integration with mainstream BMS systems in building scenarios. Residential Project SegmentWe provide top-tier HVAC system control solutions for fine decoration real estate projects, meeting both the aesthetic match of fine décor and intelligent linkage with other systems.

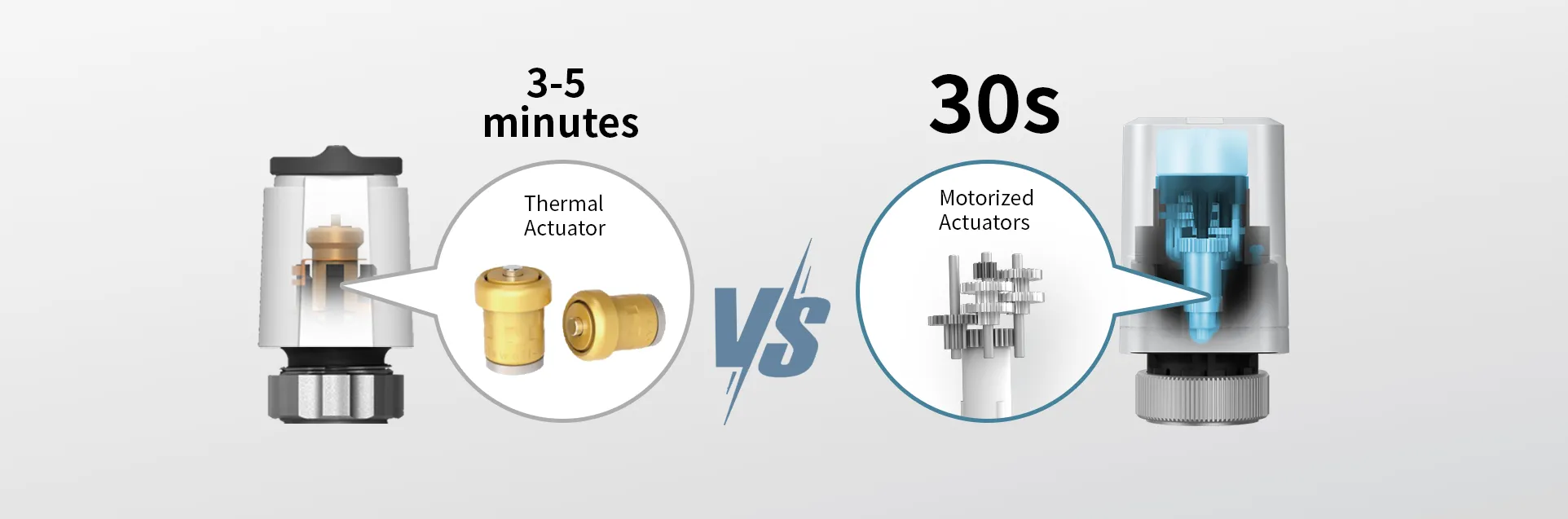

Residential Project SegmentWe provide top-tier HVAC system control solutions for fine decoration real estate projects, meeting both the aesthetic match of fine décor and intelligent linkage with other systems. Large-Scale DIY Retail & E-Commerce SegmentAs a leading brand in TRV (Thermostatic Radiator Valve) control technology, we provide mature HVAC control product kits for supermarket and e-commerce channels, helping channels quickly achieve scaled sales.

Large-Scale DIY Retail & E-Commerce SegmentAs a leading brand in TRV (Thermostatic Radiator Valve) control technology, we provide mature HVAC control product kits for supermarket and e-commerce channels, helping channels quickly achieve scaled sales. Energy-Saving Retrofit SegmentLeveraging professional system integration with wireless technology, we support various public spaces like offices, hotels, and shopping malls to implement energy-efficient solutions, achieving intelligent lighting, air conditioning, and facility management.

Energy-Saving Retrofit SegmentLeveraging professional system integration with wireless technology, we support various public spaces like offices, hotels, and shopping malls to implement energy-efficient solutions, achieving intelligent lighting, air conditioning, and facility management. Pro Home Improvement SegmentAs a leading supplier in the HVAC automatic control field, we provide residential HVAC control systems with localized implementation capabilities for the home decoration retail market, balancing installation delivery and user experience.

Pro Home Improvement SegmentAs a leading supplier in the HVAC automatic control field, we provide residential HVAC control systems with localized implementation capabilities for the home decoration retail market, balancing installation delivery and user experience. -

About

Global Partner for Innovation and Reliability in HVAC ControlsSaswell always been our core goal to serve as a solid backing for customers in consolidating their leading position in the market, while providing Fast-customized solutions to high-quality customers worldwide.LEARN MORE

Global Partner for Innovation and Reliability in HVAC ControlsSaswell always been our core goal to serve as a solid backing for customers in consolidating their leading position in the market, while providing Fast-customized solutions to high-quality customers worldwide.LEARN MORE - News

- Partners